How Industrial Scales Can Streamline Your Business Procedures

How Industrial Scales Can Streamline Your Business Procedures

Blog Article

Enhance Your Service Procedures With Reliable Industrial Scales

In today's competitive landscape, the precision of commercial ranges plays a pivotal role in improving general service operations. Accurate considering not just mitigates pricey discrepancies throughout various sectors, such as production and logistics, but additionally makes sure compliance with rigid industry standards. As businesses seek to enhance performance, understanding the different kinds of scales and their technological developments ends up being important. The option procedure can be complicated, and the ramifications of these options can significantly influence operational success. What elements should be taken into consideration to make sure the ideal devices is picked for your specific requirements?

Significance of Accurate Considering

Accurate considering is crucial in different commercial applications, as even minor inconsistencies can lead to significant operational ineffectiveness and economic losses. Industries such as production, logistics, and food handling depend upon precise measurements to guarantee product high quality, regulatory conformity, and optimal source management. Incorrect weights can result in overproduction, waste of resources, or poor supply, influencing profitability and customer fulfillment.

Furthermore, exact considering is essential for security and ecological conformity. For example, in the chemical market, incorrect dimensions can lead to incorrect combinations, leading to lawful ramifications or unsafe situations. Moreover, in the food industry, accurate considering is crucial for sticking to nutritional labeling demands, guaranteeing that consumers get precise details concerning the products they buy.

The combination of trusted commercial ranges not just enhances functional performance however additionally supports data-driven decision-making. Spending in top quality commercial evaluating solutions is critical for organizations intending to preserve an affordable edge in today's vibrant market.

Sorts Of Industrial Scales

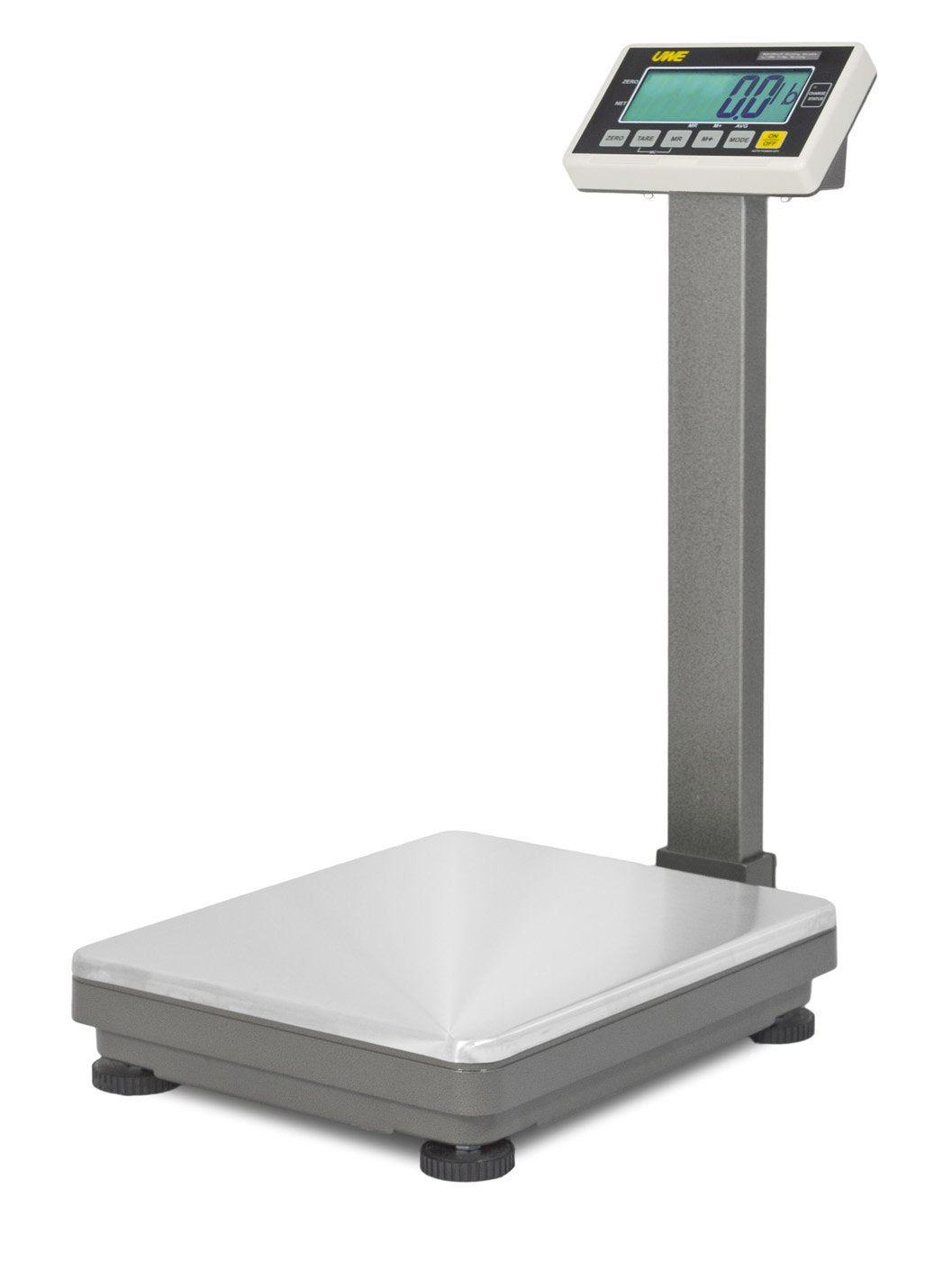

Industrial ranges come in different types, each developed to meet certain considering requirements across different fields. Amongst one of the most common types are platform ranges, which supply a big weighing surface area suitable for hefty things, making them ideal for warehouses and manufacturing facilities. These scales often feature electronic displays for simple reading.

An additional kind is bench ranges, which are usually smaller and mobile, perfect for use in research laboratories or retail settings. They permit fast measurement of smaller products while keeping precision. For applications requiring the weighing of fluids, storage tank ranges are particularly developed to measure the weight of tank, making sure specific inventory monitoring.

Crane scales are also significant; they are suspended from a framework to evaluate heavy products in commercial setups. Each kind of commercial scale serves an unique purpose, enhancing operational performance throughout varied industries.

Advantages of Modern Technology

Additionally, contemporary commercial ranges usually come equipped with connection functions that enable smooth combination with various other systems, such as stock management and manufacturing monitoring. This interconnectivity fosters a much more cohesive workflow and reduces downtime, as organizations can monitor efficiency metrics and make data-driven choices quickly.

In addition, numerous modern scales provide personalized setups and user-friendly user interfaces, permitting operators to adapt their equipment for details functional demands. Improved resilience and resilience against rough ecological problems additionally add to the long life and reliability of modern-day ranges, guaranteeing they can stand up to the rigors of commercial usage.

Choosing the Right Devices

Different industries may require distinct sorts of scales, such as flooring ranges for heavy loads, bench scales for smaller items, or portable scales for flexibility. In addition, considering the environment in which the scales will be utilized is essential. For example, tools made use of in rough settings might require to be tough and resistant to dust, moisture, or severe temperature levels.

Another crucial variable is the modern technology made use of in the ranges. Digital ranges usually supply enhanced precision and convenience of use, while analog scales might be enough for less demanding applications. It is crucial to review the scalability of the equipment, guaranteeing that it can suit future development or modifications in production procedures.

Finally, companies need to take into consideration the online reputation and reliability of suppliers, as investing in high-quality tools can result in long-lasting price financial savings and boosted operational performance.

Maintenance for Durability

Regular maintenance is necessary for ensuring the longevity and optimal efficiency of industrial scales. A systematic approach to maintenance not only extends the life of the tools however additionally assures exact measurements crucial for functional effectiveness.

Begin with regular assessments to determine damage, making certain elements such as lots cells and displays work correctly. Calibration checks ought to be conducted consistently, ideally after substantial adjustments in ecological problems or complying with heavy use. Accurate calibration is important for compliance with sector criteria and for maintaining the integrity of weight measurements.

Cleaning is an additional essential aspect of maintenance. Dirt, debris, and corrosive compounds can impair performance and lead to mistakes. Usage proper cleansing agents and methods to safeguard delicate parts. Additionally, it is advisable to develop a maintenance go to the website schedule that records each service visit, calibration, and any type of repair work carried out. This documents help in monitoring equipment efficiency and preparation for future upkeep demands.

Lastly, training staff on proper use and care click here to read methods will certainly lessen the likelihood of driver error, better boosting scale reliability. By focusing on regular upkeep, organizations can make certain that their commercial ranges remain a reliable possession in their procedures.

Final Thought

In recap, the combination of trusted commercial ranges is vital for boosting business procedures throughout various sectors. Regular upkeep and training additional contribute to the durability and precision of these scales, fostering data-driven decision-making and eventually sustaining general company success.

Industrial scales come in various kinds, each created to fulfill details weighing requirements across different markets. Crane scales are likewise noteworthy; they are put on hold from a structure to evaluate heavy products in commercial setups.Various industries may require unique kinds of scales, such as flooring ranges for heavy tons, bench scales for smaller items, or portable scales for versatility - Industrial Scales. Digital ranges frequently supply improved accuracy and convenience of usage, while analog scales might be adequate for less requiring applications.In summary, the assimilation of reliable industrial scales is vital for enhancing company operations throughout different markets

Report this page